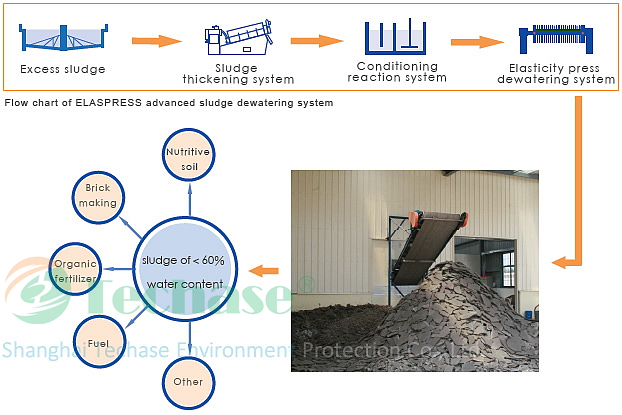

Elaspress Advanced Sludge Dewatering System:

This is a completed solution developed by Tongji University and used for advanced sludge dewatering , the core equipment of which is the super-high pressure filter press.

Application & Benefits:

It's used to directly process raw sludge or wastewater even with over 99% water or dewatered sludge with 80% moisture to get dryest filter cakes with less than 60% moisture, with cost saving, high efficiency and system simplification especially being taken into consideration.

While the volume of the raw sludge or wastewater is so significantly reduced that quite much transport cost is greatly saved.

Furthermore, after 2~3 days' natural air drying and vaporation, the moisture content of the sludge cakes can reduced to 40~50%. Then they are dry enough to meet the national landfill standard requirements and can be recycled as useful materials such as brick making and fuel.

Principal System Components:

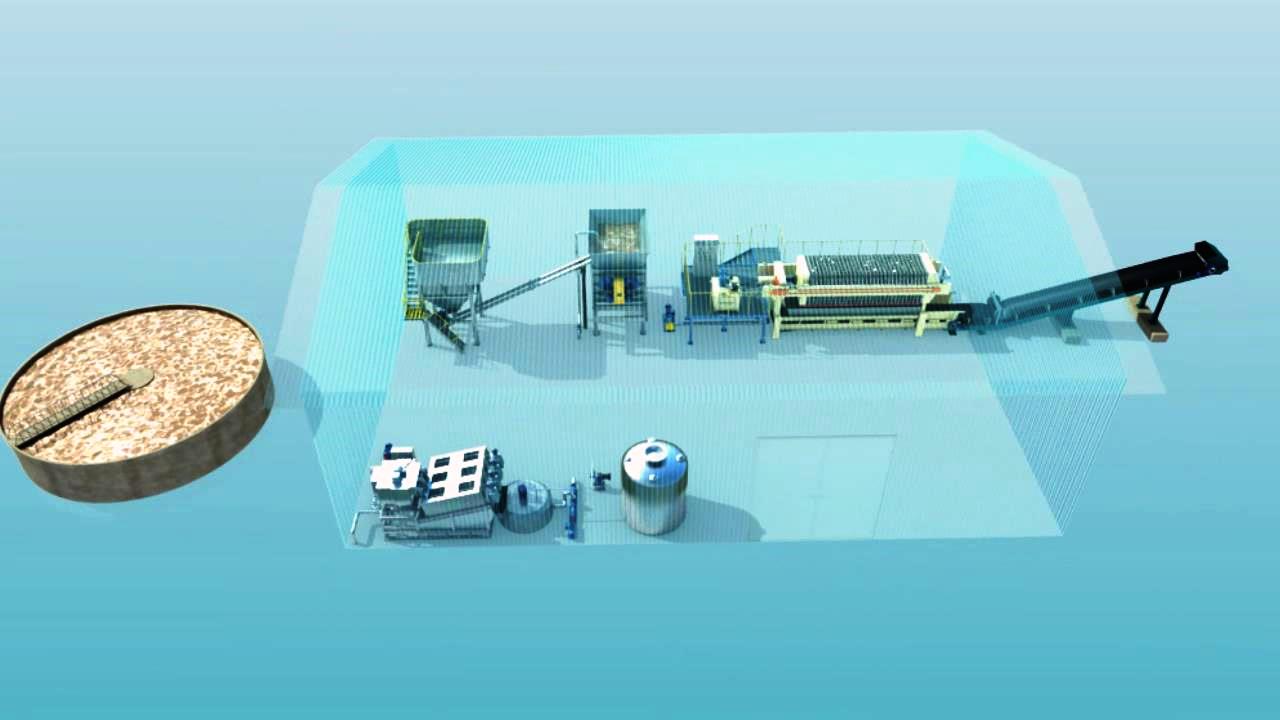

A typical Elapress Advanced Sludge Dewatering System consists of 3 processes which are thickening, conditioning and pressing.

●Wastewater Pre-thickening System:

Multi-plate Screw Thickener is a screw type sludge thickenening equipment developed by TECHASE, used to preliminarily reduce the volume of the wastewater with 99% water and get slurry with 90%~95% moisture;

●Slurry Conditioning System:

FeCl3 and curing agent are dosed into to act with the slurry to break the cells wall and structure of the slurry and release the fluid in the cells. The conditoned slurry is easier to be dewatered dryer.

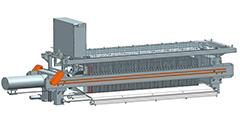

●Advanced Dewatering System:

The super-high pressure filter press is applied for pressing and filtrating the conditioned slurry under high pressure to get much dry sludge cakes with less than 60% moisture. After 2~3 days' natural evaporation, the moisture content can be further reduced to 40%~50%.

Features & Advantages:

Compared with other types of filter presses system, this system is 3~4 times more efficient and much easier-to-manage. Other advantages as below:

※Compact placement & less facilities require much less area.

※Procuce no seconday pollution

※Less equipment and devices, lower investment cost and managemetn cost

※Stable & high performance

※Less maintenance cost