In recent years, the concept of green

development deeply rooted in the hearts of the people, with the number of

wastewater treatment plants in China has increased significantly, the volume of

wastewater treatment has increased significantly, and the wastewater treatment

capacity has been improved rapidly. In this context, the nation has put forward

policies such as the Water Pollution Prevention Action Plan (Water Ten) to set

higher requirements for national wastewater treatment standards. Therefore, how

to upgrade standard and improve the efficiency of wastewater treatment plants

has become a hot issue.

In order to satisfy the technical

requirements for the upgrading of wastewater treatment plants under high

emission standards, on August 27, 2019, the "China Water Supply and

Drainage" magazine cooperated with China Municipal Engineering North China

Design and Research Institute, China Municipal Engineering Central and South

China Design and Research Institute and more than ten institutes and the

companies held the "2019 China Drainage System Quality Improvement Conference"

in Ningbo, Zhejiang. Invited the leaders of the Ministry of Housing and

Urban-Rural Development, the China Civil Engineering Society, the China Urban

Water Supply and Drainage Association, and other experts in the national

drainage industry to interpret industry policies, share typical success cases

of wastewater treatment and upgrade, and discuss the future direction of

technology development, build platform of new technologies, new processes and

new equipment for wastewater treatment and upgrading introduction.

As an environmental protection company with

a large number of independent research and development of advanced technology

and plenty of practical experience, Mr. Liu Daoguang, Vice President of Techase

and Director of Technology Center of Techase, gave a speech in the topic of

“New Sludge Deep Dewatering Treatment System--Continuous Green Conditioning and

Fast High Pressure Press”, With continuous green conditioning technology, fast

high pressure filter press technology and equipment module integrates developed

by Techase in many practical cases, we proposed an effective upgrading plan of

sludge treatment. The speech caused great response and unanimous recognition

from the participants.

The New Sludge Deep Dewatering Treatment System

Industry Background

As a concentrate of pollutants after

wastewater treatment, sludge will cause more serious secondary environmental

hazards if handled inadvertently. The four major problems of sludge dewatering

are:

1. The

addition of iron salt and lime affects the sludge property. The powder

injection seriously affects the actual quantity of the sludge treatment and

limits the utilization of resources.

2. Traditional

press equipment has lower pressure and efficiency, higher energy consumption

and costs of spare parts replacement, larger footprint.

3. Low

level of concentration and conditioning equipment integration. Cannot satisfy

the industry dewatering requirements.

4. The

system is cumbersome, low level self-control, bad performance, and easy to

produce stench.

Technology Introduction

The new sludge deep dewatering treatment

system developed by Techase has been developed the technology new through the

old. By continuous green conditioning of the sludge, adding powder-free chemicals

to destroy the sludge cement structure and change the properties of the

particles so that reducing the water holding capacity and filtration resistance

of the sludge, and then effectively reduce the sludge. At the same time, the

process adopts a fully automatic control system, coupled with high-pressure

equipment such as super high pressure filter press, which can quickly reduce

the moisture content of sludge to below 50%, effectively improving the quality

and efficiency of sludge treatment. The modularization and integration of the

equipment has greatly reduced the cost of maintenance and replacement of the

equipment, thereby improving the efficiency of sludge treatment. Finally,

aerobic composting and other technologies can be used to make the sludge be

used in fields such as gardens to realize sludge resource utilization. The new

sludge deep dewatering treatment system not only brings convenience to the

subsequent sludge treatment, but also pay attention to the economic and

environmental balance of the sludge treatment and disposal process.

Technical Process

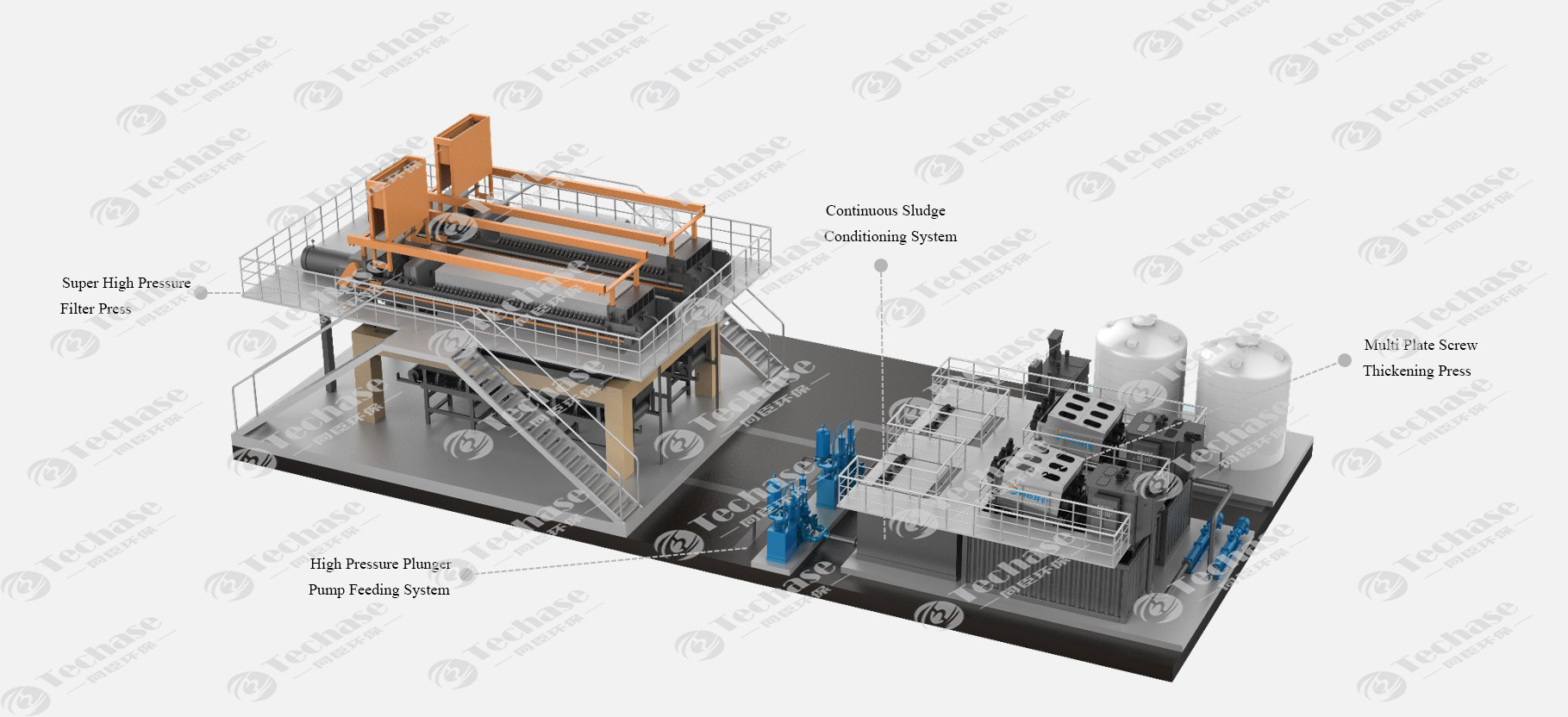

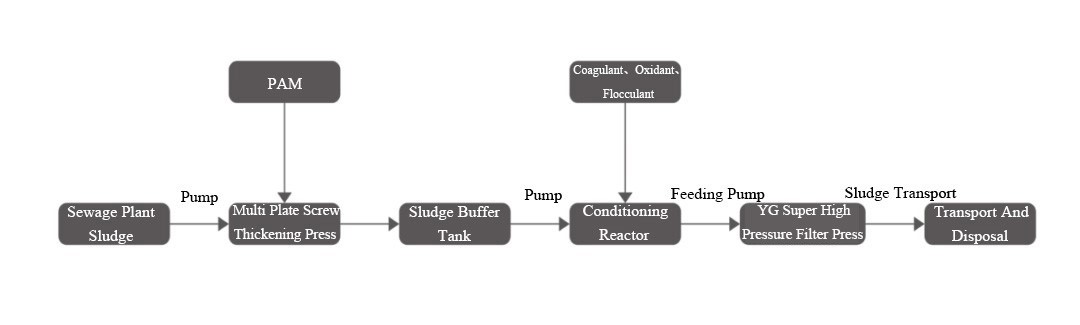

The new sludge deep dewatering treatment

system consists of four main parts: multi-plate screw thickening press,

continuous sludge condition system, super high pressure filter press, high

pressure plunger pump feeding system. Sludge is concentrated in multi-plate

screw thickening press with PAM, and then placed in the sludge buffer tank;

then pump into the continuous conditioning reactor for conditioning

modification with adding powder-free agent; finally, feeding pump sends the

sludge to the super high pressure filter press for pressing treatment, the

sludge cake after dewatering can be transported or recycled.

Technical Advantages

1.2.5~10MPa high pressure press, low

moisture content (50%~55%), high quality;

2. Integrate equipment and standardization

to reduce civil construction requirements and effectively save equipment costs

and land area;

3. Environment friendly liquid

conditioning, no powder feeding, thereby no increased dry solid, which is

conducive to subsequent resource utilization;

4. Reduce energy consumption by 30% and

spare parts replacement costs by more than 50%;

5. Fully automatic control system, the

system is easy to operate and maintain, and the site environment is neat and

friendly. Operation management is simple and efficient;

Application Cases