With the increasing awareness of environmental protection of whole society, the importance of sludge treatment after wastewater treatment has been well known. However, the price of advanced sludge treatment equipment, such as multi-plate screw press, is still slightly higher for some small wastewater treatment stations, factories and farmers. Moreover, some factories are limited to the terrain and environment of the plant so that it is impossible to treat sludge by multi-plate screw press. So is there a way to make it possible for multi-plate screw press to meet the demand of customer and unlimited to terrain condition?

This problem seems simple, but it is very difficult to practice. Because it is impossible to change the complex and varied site conditions, and cannot make multi-plate screw press any changes fit the site. So what should we do? Author still could not think out a perfect solution, so author has to ask the colleagues in the environmental research and development department of Techase for help to find a solution. Looking at author’s scratching, the colleagues tried to hold their laugh and brought author to the front of a small truck.

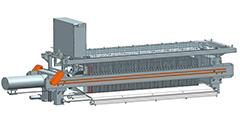

This truck compartment looks no different from the ordinary minivan. What is the secret? After the car was opened, author found that there was a multi-plate screw press in it. Is it a car pulling a multi-plate screw press to treat the sludge? The treatment of sludge can be done without only one multi-plate screw press. However, when author saw colleagues' self-confidence, author felt that things were not simple like it showing. So after checking carefully again, that compartment can really be said that "the sparrow may be small but it has all the vital organs." In the compartment, not only the multi-plate screw press, sludge pump, dosing equipment and other dewatering facilities are also available. It is simply a small sludge treatment plant that can be moved. Colleagues from the R&D department told author that this is the TCEM mobile dewatering system developed by Techase in order to meet market demand.

The TCEM mobile dewatering system is simply to integrate the vehicle-specific multi-plate screw press, dosing device, sludge pump, electric control cabinet, generator and other parts into a small truck compartment. The entire dewatering system can be easily carried on a minivan. In this way, the entire dewatering system can be put into operation as long as the car is driven to a location where sludge treatment is required. Making the workplace no longer is a problem that affects sludge dewatering. Coupled with advantages of small and flexible, energy-saving and high-efficiency, running continuously and uneasy to block. It can be fully displayed in the narrow space of the truck compartment.

Listening to the introduction by colleagues, author could not help but give a thumbs up. In this way, the advantages of energy-saving and high-efficiency of our multi-plate screw press perfectly combine with the excellent flexibility of small trucks, Not only does it guarantee the advantages of both, but it also reduces the footprint. The most critical is that this TCEM mobile dewatering system saves a lot of sludge treatment costs for a large number of end-user customers.