With the continuous advancement of

urbanization and the continuous development of social economy, the problem of

river pollution has become more serious. In recent years, the state's

governance to control rivers have continued to increase, and the effects have

continued to improve. However, at the same time of governance, it faces new

environmental problems. What is the treatment of huge river sludge?

In the process of dredging, the river will inevitably produce a large amount of sludge. These sludge generally have high water content and low strength. Some of the sludge may also contain toxic and harmful substances. If not properly treated, it will cause secondary pollution to the surrounding environment. At present, according to the principle of reduction, harmlessness and resource utilization of solid waste treatment, require the sludge treatment can realize the resources utilization as much as possible. In domestic, the sludge resource regeneration technology such as sludge brickmaking, ceramsite, curing, drying and soiling are used in the sludge resource treatment of river.

River Sludge

Sludge Brick Making

The river sludge contains a large amount of inorganic matter, which can be used as a raw material for building such as bricks, cement and ceramsite. The resource utilization of sludge in building materials is currently in a stable development trend, and it is an effective treatment method with relatively mature technology and relatively obvious social and economic benefits. The traditional method of sludge bricks is to convert sludge into building materials by heating and sintering. However, the high energy consumption and secondary pollution caused by harmful gases generated in the incineration process are also the shortage of traditional sludge brick technology.

Hydrothermal Brick Making

This technology is a non-burning preparation technology for sludge developed by Techase Union Tongji University of Materials Science and Engineering college, based on hydrothermal curing technology. It is a method of pressure forming and heat curing separate to simulate the groundwater thermal diagenesis. The sludge is firstly deep dehydrated, and then the non-burning preparation technique is further employed after the harmful components and heavy metal components contained in the dried sludge are coagulated and stabilized.

The specific process: crushing the dried

sludge cake to particles with a particle size of less than 3 mm; adding a

curing agent and other additives to the crushed powder, and thoroughly mixing;

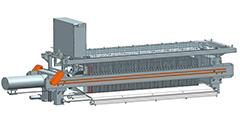

the raw material mixture after the mixing is transported to the automatic

hydraulic brick machine by the conveyor belt. and then press moulding by a

high-pressure provided by oil pump and hold pressure, and then pre-curing; the

raw embryo after the completion of the curing is sent to the hydrothermal

reaction kettle, and then the steam generated by the steam boiler is

pressurized and heated. After a certain period of time, high-strength sludge

bricks can be obtained, which can be turned into products after drying,

grinding and other processes.

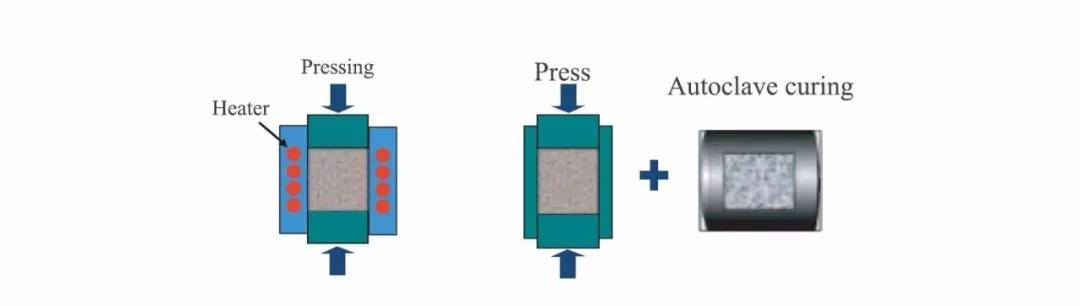

(Hydrothermal

Reaction Diagram)

(Hydrothermal

Reaction Kettle Photo)

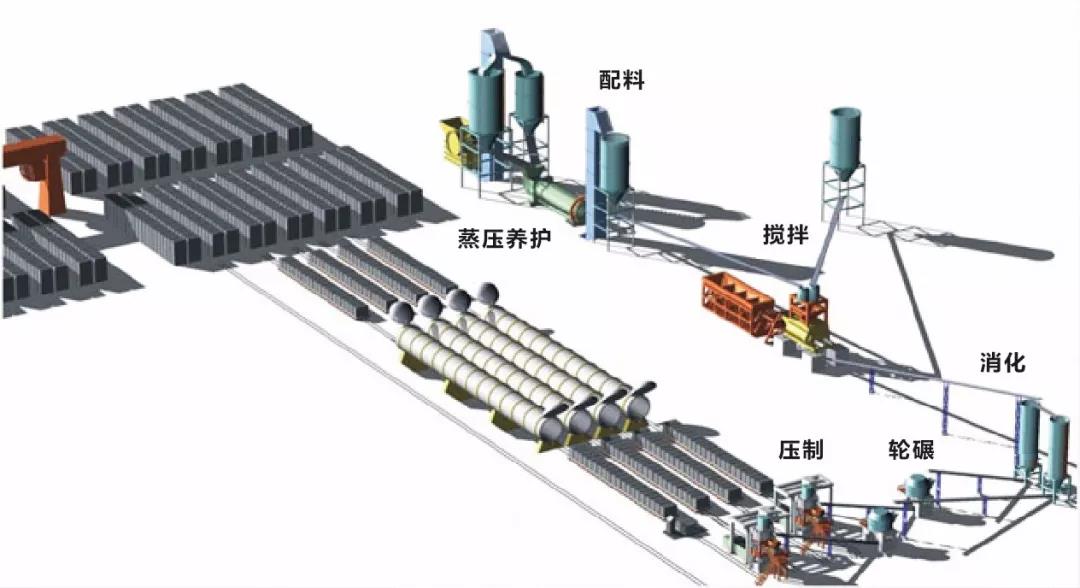

(Production

Line Diagram)

The use of hydrothermal curing technology to make sludge bricks can avoid the harmful gases generated during high-temperature incineration and the waste of resources caused by incineration. It not only overcomes the problems of crystal transformation, decomposition and volatilization which are insurmountable in some high-temperature preparations, but also has low production cost and uniform particle size of the cured product. In the low-cost case, the sludge is made into an environmentally friendly non-burning brick, and the sludge is turned into treasure. It is a new technology that is very environmentally friendly and has a lower production cost than the cement-sand-free brick.

Technical Advantages:

1. The utilization rate of sludge is high,

and the utilization rate is up to 85%;

2. The reaction temperature is low (≤200°C), the

energy consumption is small, and the production process is energy-saving and

environmentally friendly;

3, The product has a wide range of

applications, can deal with a variety of solid waste including river sludge,

construction waste, slag, etc., making it into a high value-added brick

material, to achieve turning sludge waste into treasure;

4, High product strength, durability, frost

resistance, acid and alkali resistance, high added value;

5, Hydrothermal curing technology can fix

heavy metal ions and adsorb harmful substances to avoid secondary pollution;

6, Can prepare humidity control materials, superior moisture absorption and release performance, is an ideal ecological material.

Hydrothermal Curing Product Features:

1. The product has high strength, and its

strength is more than 3 times of ordinary wall and floor tiles, and the

durability and frost resistance are good;

2, hydrothermal curing can fix harmful ions

to dissolve, solve the problem of heavy metal dissolution;

3, the product simulates the accumulation

of rock diagenesis process, inorganic stone material, a new type of artificial

stone, the performance is better;

4, the curing temperature is low, the energy

consumption is about 1/6 of the ordinary building materials burning process,

the environmental load is small, and can be recycled;

5, the production process cycle is short,

which is about the 1/3 of the ordinary firing process.

Part of the Application Cases

1. Project Site of Jinshan District

Three fish ponds in Jinshan District of

Shanghai, use sludge-based biochar slope protection materials as reef and slope

protection materials with a total area of 7,000 m2.

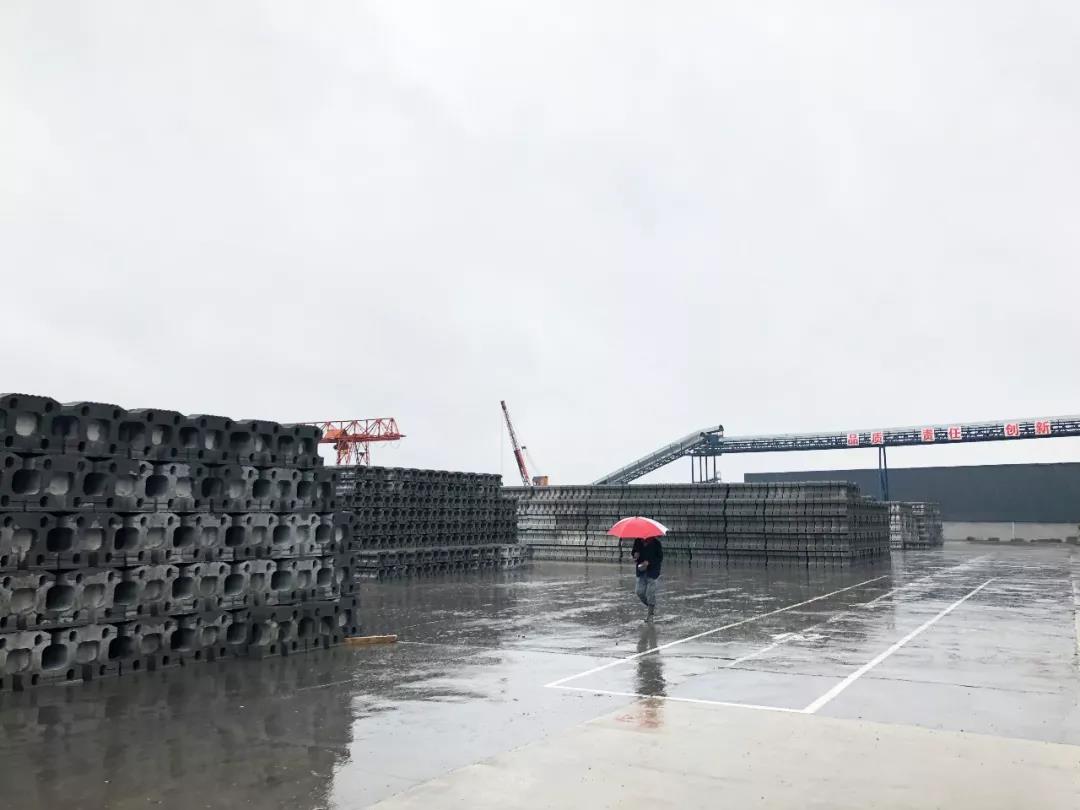

2. Factory in Haiyan

3. Factory in Yaozhuang

In recent years, Techase has devoted itself

to the field of river sludge resources research and development. In order to

achieve the requirements of sludge reduction, harmlessness and resource

utilization, we will continue to strengthen and realize the maximum utilization

value of sludge, reduce the treatment cost of sludge, and make continuous

efforts to achieve the final conversion of sludge utilization.