Guide

In order to arouse public awareness of water conservation to strengthen the protection of water resources, the forty-seventh session of the UN General Assembly in 1993 made a resolution to determine March 22 as "World Water Day". With population growth and economic development, people's irrational use of limited water resources has caused tremendous impact on the water environment. Some problems such as water pollution and deterioration of water environment have become an international problem. In 2015, the State Council issued the "Water Ten" (water pollution prevention action plan)officially pushed this environmental issue to a climax, and the governance of water resources is imminent.

In response to the development of the national “Water Ten”, Shanghai Techase Environment Protection Co., Ltd (Hereinafter referred to as Techase) has been exploring and innovating in the field of waste water treatment for many years, striving to create high-quality, high-performance waste water sludge treatment equipment and solutions. At present, the environmental protection equipment produced by Techase has been applied to many industries such as petrochemical, papermaking, printing and dyeing, pharmaceutical and fruit and vegetable processing, and the project cases are spread over more than 80 countries and regions.

Recently, Techase visited Jiaxing of

Zhejiang province, which is known as the “Land Of Plenty” and “The House Of

Silk”. As an important city in the Yangtze River Delta urban agglomeration,

“production service-oriented national logistics hub carries the city”, Jiaxing

is still growing and developing in both agriculture and industry day by day.

The deep visit this time will explain the case analysis of the Techase multi

plate screw press machine in Jiaxing Petrochemical Industry.

Case Background

This project is for a petrochemical limited

liability company which located in an industrial park in Jiaxing, Zhejiang. The

company mainly produces chemical products such as Propylene, propane, mixed

aromatics, benzene, toluene, mixed xylene, heat transfer fluid, MTBE, liquefied

petroleum gas, liquid sulfur by using raw materials such as fuel oil and

naphtha by the technology of Catalytic cracking, hydrorefining, aromatic

extraction, separation, etc. The raw material processing capacity is 800 to 1.2

million tons/year. Part of the chemical products produced are supplied to

neighboring enterprises in the industrial park to realize the development of

circular economy and low-carbon economy in the industrial park.

Generally speaking, the petrochemical

industry is different from other industries. The oily sludge produced in the

production process is complex and highly toxic, and has the characteristics of

poor fluidity, high viscosity, and a large amount of organic and inorganic chemicals.

If these sludge are directly discharged without harmless treatment, they will

cause serious pollution to the surrounding environment, even affect people's

health and safety. Moreover, the oily sludge contains a lot of petroleum

resources, and direct discharge will also cause waste of resources.

Solution

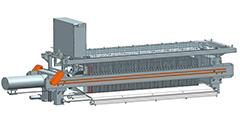

The project adopts the multi plate screw

press machine of Techase, for the characteristics of oily sludge in the

petrochemical industry, our filter body adopts petrochemical special shaft type

and enhanced drive system, which is suitable for the flow characteristics of

materials in the petrochemical industry. The moving and fixed rings adopts

higher anti-corrosion materials, in order to adapt to the high chloride ion

operating environment in the petrochemical industry; the overall equipment ups

to the explosion-proof grade of ExdllBT4, meets the strict explosion-proof

requirements of the petrochemical industry.

Equipment Advantages

1

The filter body adopts the special shaft type of long-type sludge, which can

meet the high-efficiency dehydration of various oil sludge (including 100 °C

high temperature materials);

2

The screw is processed by surfacing super-abrasive hard alloy material and

processed through 6 steps;

3 It

adopts special design such as special sludge flocculation tank for sludge, and

the dosage is small, which overcomes the problems of difficult flocculation and

easy deposition of petrochemical sludge;

4

The equipment has a good self-cleaning function to avoid the blockage of

high-viscosity sludge to conventional equipment;

5

The equipment has small footprint, light weight, simple structure and less

system equipment;

6 Enhanced drive system can meet the large driving force requirements for oily sludge.

Through the system treatment of the multi-plate screw press machine, treatment difficult for oily sludge is effectively solved. After sludge treatment, the moisture content of the sludge reaches 80%. At present, the equipment is running stably and the site effect is good, which is highly praised by customers.

Techase has been deeply immersed in the

waste water sludge treatment industry for many years, providing targeted system

solutions for customers in different industries based on different industry

characteristics and combining the company's technological innovation

advantages. Industry-specific machines and system solutions have been launched

in petrochemical, paper, pharmaceutical and fruit and vegetable processing

industries.