The Nannehe River Treatment Project in Leping City, Jiangxi Province is located near the station of Leping City, which is close to Linjiang Street. Semi-dry/dry method was adopted to clear sludge in Nannei River. The total sludge treatment capacity was 140,000 mm3 (under water), the sludge moisture content was 80%, and the sludge disposal period was six months. The sludge dewatering treatment covered an area of 3400m2, of which the super high pressure filter press system area covered 770m2.

After being dehydrated by the filter press, the moisture content of the sludge cakes were as low as 40%, and one operation batch was one hour, in which the sludge feeding spent 45 minutes and the sludge cakes discharging spent 15 minutes.

Process description:

1. The river sludge is pumped to the garbage sorter, and the large particle impurities and plastic garbage are separated out. The underflow material enters into the sludge tank, and the waste on the screen is disposed of by external transportation;

2. The sludge in the tank is lifted to the conditioning tank by the lifting pump. The sludge pump is set as a floating pump, which can be moved as required.

3. The sludge enters into the conditioning tank. Under the impact of the stirring device, the flocculants such as PAC and PAM are fully mixed with sludge to regulate the sludge dehydration performance.

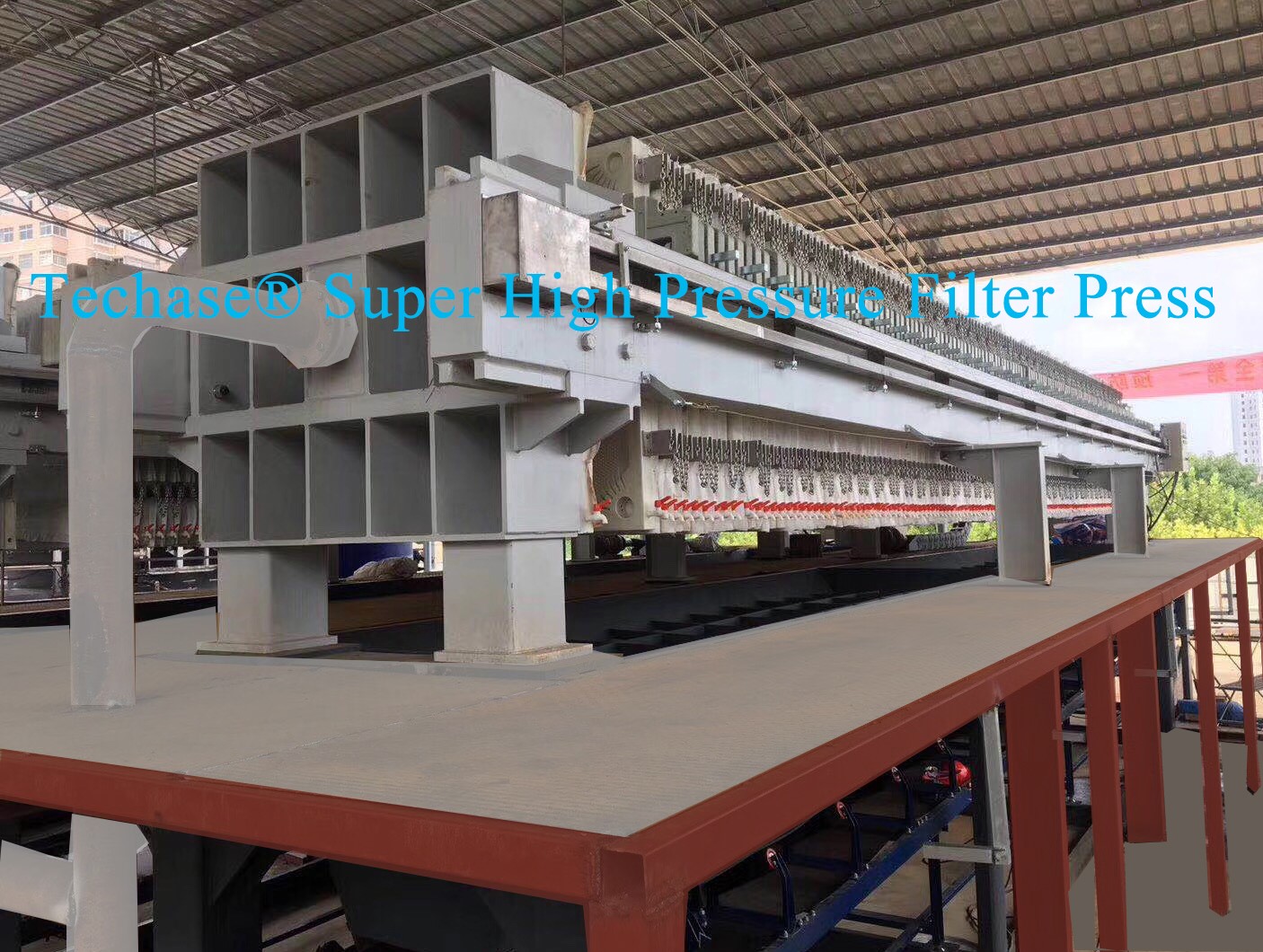

4. The conditioned sludge is transported to the filter press through the plunger pump for dewatering. Sludge cakes are transported and treated outside belt conveyor, and the filtered water is discharged to the drain through the filtrate collection tank.