Building Slurry

With the least amount of organic matter, relatively stable composition and performance, best mechanical performance and less pollution, the building slurry can be used as building materials, filling soil or greening soil after dehydration and improvement. There will be more and more waste slurry and building slurry produced with the continuous development of the city.

At present, the conventional treatment method of building slurry is to use canned slurry truck for external transportation and slurry deposition and drying on site. However, both of them have serious limitations. On the one hand, for the external transportation of slurry, due to its large production volume, high water content and flowing shape, about 75% of the actually transported slurry is water, which greatly increases the treatment cost and may cause environmental pollution in the transport process. On the other hand, it needs to occupy a large area of land, resulting in soil compaction and waste. Moreover, the large tonnage of slurry trucks is a serious safety hazard to municipal roads and bridges, which occupying our already congested urban road resources and frequently causing various traffic accidents.

At present, from the central government to the local government, various favorable policies are emerging frequently. In terms of environmental governance, laws and regulations of China's environmental protection industry are gradually standardized, and the building waste section has become the optimal section for the disposal of solid waste industry. However, in the disposal of building waste, the treatment and reduction of building slurry is very difficult.

Building slurry has two characteristics. First, a large amount of slurry can be produced in a short time once the construction machinery is started. Second, it is difficult to store. There is no big slurry tank on site. So if you discharge it directly, it will pollute the environment. And the car transportation costs are high, so local processing is the best option. In order to solve the existing problems of building slurry, we have developed and innovated independently. Taking the special multi plate screw press for pile foundation slurry as the core equipment, we have systematically integrated the slurry pretreatment, adjustment, transportation and external transportation equipment technology, and then put forward the system solution of the pile foundation slurry dewatering treatment. This solution can solve the existing problems in the process of pile foundation slurry treatment and reduce customers’ investment and operating costs. We have accumulated a large number of practical operation parameters of slurry treatment in various construction sites, and further launched the integrated system of vehicular mobile slurry dewatering.

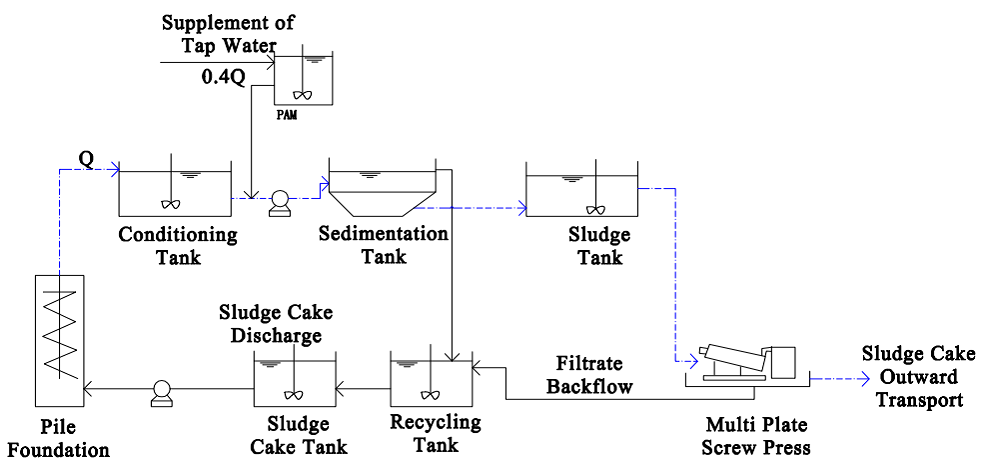

Process route:

At present, the conventional treatment method of building slurry is to use canned slurry truck for external transportation and slurry deposition and drying on site. However, both of them have serious limitations. On the one hand, for the external transportation of slurry, due to its large production volume, high water content and flowing shape, about 75% of the actually transported slurry is water, which greatly increases the treatment cost and may cause environmental pollution in the transport process. On the other hand, it needs to occupy a large area of land, resulting in soil compaction and waste. Moreover, the large tonnage of slurry trucks is a serious safety hazard to municipal roads and bridges, which occupying our already congested urban road resources and frequently causing various traffic accidents.

At present, from the central government to the local government, various favorable policies are emerging frequently. In terms of environmental governance, laws and regulations of China's environmental protection industry are gradually standardized, and the building waste section has become the optimal section for the disposal of solid waste industry. However, in the disposal of building waste, the treatment and reduction of building slurry is very difficult.

Building slurry has two characteristics. First, a large amount of slurry can be produced in a short time once the construction machinery is started. Second, it is difficult to store. There is no big slurry tank on site. So if you discharge it directly, it will pollute the environment. And the car transportation costs are high, so local processing is the best option. In order to solve the existing problems of building slurry, we have developed and innovated independently. Taking the special multi plate screw press for pile foundation slurry as the core equipment, we have systematically integrated the slurry pretreatment, adjustment, transportation and external transportation equipment technology, and then put forward the system solution of the pile foundation slurry dewatering treatment. This solution can solve the existing problems in the process of pile foundation slurry treatment and reduce customers’ investment and operating costs. We have accumulated a large number of practical operation parameters of slurry treatment in various construction sites, and further launched the integrated system of vehicular mobile slurry dewatering.

Process route:

Technological characteristics:

1.Sand moisture content after treatment is less than 30%, which greatly reduces the volume of slurry, facilitates transportation and subsequent treatment.

2.The sand content of slurry after treatment is less than 5%. So it extends the service life of the equipment and improves the economic benefits.

3.The energy consumption of the process is low, which is only 20% of centrifuge dewatering machine. The screw shaft of the special multi plate screw press of slurry is more suitable for the pile foundation slurry with high content of inorganic material.

4.The equipment has low rotate speed, stable operation, low noise, convenient operation and management, small footprint and large capacity of treatment.

5.You can choose system of vehicular mobile slurry dewatering, which is more flexible and convenient.

6.We will provide operation treatment service for customers.

1.Sand moisture content after treatment is less than 30%, which greatly reduces the volume of slurry, facilitates transportation and subsequent treatment.

2.The sand content of slurry after treatment is less than 5%. So it extends the service life of the equipment and improves the economic benefits.

3.The energy consumption of the process is low, which is only 20% of centrifuge dewatering machine. The screw shaft of the special multi plate screw press of slurry is more suitable for the pile foundation slurry with high content of inorganic material.

4.The equipment has low rotate speed, stable operation, low noise, convenient operation and management, small footprint and large capacity of treatment.

5.You can choose system of vehicular mobile slurry dewatering, which is more flexible and convenient.

6.We will provide operation treatment service for customers.